Jaw Crusher

Price 72000.00 INR/ Piece

Jaw Crusher Specification

- Motor Power

- 30 HP

- Surface

- Painted

- Product Type

- Jaw Crusher

- General Use

- Crushing stones, ores, and minerals

- Material

- Mild Steel

- Type

- Crushing Equipment

- Capacity

- 10-40 TPH

- Weight (kg)

- 3200 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual

- Cooling System

- Air Cooled

- Method

- Mechanical Force / Compression

- Voltage

- 415 V

- Dimension (L*W*H)

- 2190 mm x 1680 mm x 1800 mm

- Feature

- High Crushing Ratio, Easy Operation, Low Maintenance

- Color

- Blue and Yellow

- Noise Level

- Less than 85 dB

- Jaw Plate Material

- High Manganese Steel

- Lubrication

- Grease Cup / Manual

- Discharge Opening Range

- 25-75 mm

- Portability

- Stationary

- Application

- Mining, Construction, Aggregate Processing

- Crushing Method

- Primary Crushing

- Drive Type

- Electric Motor

- Feed Size

- Up to 300 mm

About Jaw Crusher

Product Details:

| Minimum Order Quantity | 01 Set |

| Brand | Matest |

| Material for Construction | Stainless steel |

| Voltage | 440 V, Three Phase, A.C. Supply |

| Discharge opening adjustment range | 3 - 10 mm |

We are the manufacturer of Jaw Crusher.

Features:

- Compact and rugged for laboratory and small production units

- Designed for speed crushing

- Manganese steel jaws adjustable up to 6 mm opening

- 250 kg materials can be crushed in approx eight hours

- Supported with strong steel frame

Enhanced Durability Meets High Performance

Equipped with high manganese steel jaw plates and a rigid mild steel body, this jaw crusher ensures reliable operation under demanding conditions. Its air-cooled system and grease cup lubrication extend the lifespan of vital components while minimizing service requirements. The crusher's high crushing ratio and robust primary crushing capabilities help streamline processing in mining and aggregate applications.

Effortless Operation and Maintenance

The semi-automatic control system allows for straightforward, manual adjustments of the discharge opening, making it easy to shift between different operational needs. Lubrication is managed manually via a grease cup, simplifying regular maintenance. With its user-friendly design and noise output below 85 dB, this crusher ensures a safe and efficient working environment.

FAQ's of Jaw Crusher:

Q: How does the jaw crusher function in the crushing process?

A: The jaw crusher uses mechanical force and compression to reduce the size of stones, ores, and minerals. Material is fed into the crusher's chamber where a stationary and a moving jaw plate, made of high manganese steel, crush the feed down to a specified discharge size between 25-75 mm.Q: What types of materials can be processed with this jaw crusher?

A: This jaw crusher is designed to crush a variety of materials including stones, mineral ores, and construction aggregates. It is particularly suitable for mining, construction, and aggregate processing due to its robust build and primary crushing capabilities.Q: When should jaw plate maintenance or replacement occur?

A: Jaw plates typically require inspection and maintenance at regular intervals depending on workload and material abrasiveness. When wear is observed or the crusher's efficiency drops, inspect the high manganese steel plates and replace them if thickness falls below operational limits.Q: Where is this jaw crusher best installed?

A: As a stationary piece of equipment, the jaw crusher is ideally installed at mining sites, construction locations, or aggregate processing plants where primary crushing is necessary. Its dimensions allow for indoor or sheltered outdoor placement with access to a 415 V electric supply.Q: What are the benefits of using this jaw crusher in aggregate processing?

A: Key benefits include a high crushing ratio, consistent product size, reduced noise levels (under 85 dB), and low maintenance. Its durable high manganese steel plates and user-friendly manual controls enhance operational efficiency and help lower long-term costs.Q: How is lubrication performed on this crusher?

A: Lubrication is done manually using a grease cup, ensuring that crucial moving parts remain well-lubricated for smooth operation and extended component life. Routine manual lubrication helps maintain the machine's performance and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aggregate Testing Equipments Category

Tile Abrasion Testing Machine

Price 80000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other

Control System : Manual

Computerized : No

General Use : Aggregate Test

Cylindrical Measures

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other

Control System : Manual

Computerized : No

General Use : Aggregate Test

Freezing Thawing Chamber

Price 240000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other

Control System : Manual

Computerized : No

General Use : Aggregate Test

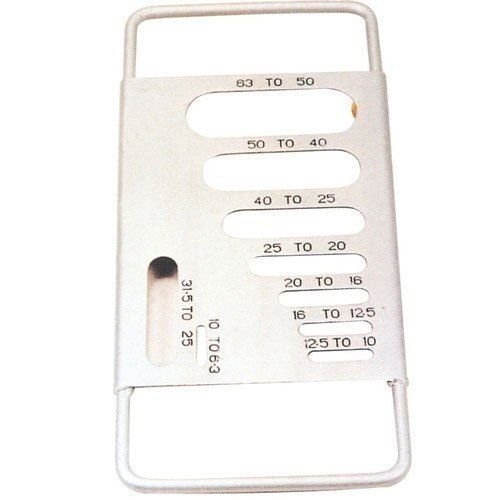

Thickness Gauge

Price 600.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other

Control System : Manual

Computerized : No

General Use : Aggregate Test

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry