Call: 08071792696

Briquette Mould

Price 5000 INR/ Piece

MOQ : 1 Piece

Briquette Mould Specification

- Surface

- Machined smooth

- Product Type

- Briquette Mould

- General Use

- For making briquette samples for laboratory analysis

- Material

- Steel

- Type

- Manual / Laboratory Mould

- Capacity

- Typically 3, 6, or 12 sample capacity

- Weight (kg)

- Approx. 5-10 kg (varies by model)

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Method

- Compression moulding

- Dimension (L*W*H)

- Approx. 200 x 100 x 100 mm (varies by design)

- Feature

- Corrosion-resistant, precision finish

- Color

- Metallic silver/grey

- Sample Shape

- Cylindrical

- Finish

- Polished

- Usage

- Ideal for coal, coke, iron ore, and mineral sample preparation

- Operating Pressure (for use)

- Up to 2000 psi (hydraulic press required)

- Accessories Included

- Plunger, base plate

- Sample Size

- Diameter 40 mm x Height 40 mm (standard); custom sizes available

Briquette Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- MADURAI

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

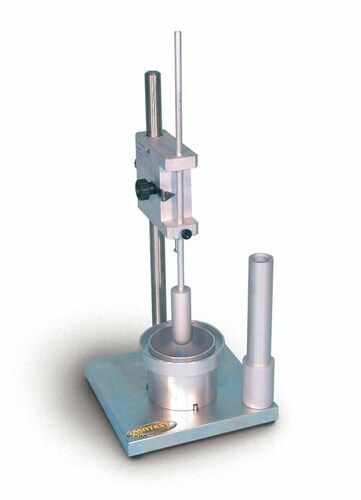

About Briquette Mould

Product Details:

| Brand | Matest |

| Material | Gun metal |

| Briquettes cast | 25.4 mm x 25.4 mm |

| Used for | Tensile strength tests |

| Base plate | Steel |

For casting of cement briquettes for tensile strength tests. It is a two part split mould made of gun metal. Two thumb screws facilitate easy and quick assembling and dismantling of the mould.

Precision Briquette Sample Preparation

Ideal for laboratory analysis, this briquette mould enables consistent sample creation for coal, coke, iron ore, and minerals. Its manual operation and rugged steel construction ensure ease and durability, while polished surfaces deliver a precision finish. With typical capacities ranging from 3 to 12 samples and custom sizes available, laboratories receive versatile, reliable performance suited to varied research needs.

High Pressure Performance and Corrosion Resistance

Built to withstand operating pressures up to 2000 psi, the mould is compatible with standard hydraulic presses used in laboratories. Its corrosion-resistant steel and machined smooth surface ensure longevity even in demanding environments. Every unit includes accessory components like the plunger and base plate for a complete briquette forming system-ready for immediate integration into sample preparation routines.

FAQ's of Briquette Mould:

Q: How do I use the Briquette Mould for sample preparation?

A: Begin by assembling the mould, placing your mineral or coal sample inside the cylindrical chamber. Position the plunger and base plate as provided. Use a hydraulic press to apply up to 2000 psi, forming the sample into a consistent briquette ideal for laboratory analysis.Q: What is the standard sample size and can I order custom sizes?

A: The standard sample size for this mould is 40 mm in diameter and 40 mm in height. Custom sizes are available upon request, allowing you to tailor the mould to specific laboratory protocols or material requirements.Q: When is this briquette mould typically used in the testing process?

A: The mould is utilized during the initial sample preparation phase, particularly when laboratory analysis requires briquetted specimens. It ensures consistent shaping before physical, chemical, or combustion tests are conducted.Q: Where can I purchase or source this briquette mould in India?

A: This product is available from various dealers, manufacturers, suppliers, distributors, exporters, and wholesalers across India. It is commonly found through laboratory equipment retailers and specialized service providers.Q: What is the compression moulding process involved?

A: Compression moulding involves placing the powdered sample into the mould's chamber, then using the manual plunger and hydraulic press to exert high pressure (up to 2000 psi). This compacts the material into a uniformly shaped briquette suitable for accurate laboratory examination.Q: Is the briquette mould suitable for both manual and laboratory use?

A: Yes, the mould is specifically engineered for manual operation, making it suitable for both laboratory and field sample preparation settings. Its robust design supports repeatable results without computerization or automation.Q: What are the main benefits of using this mould in laboratory analysis?

A: The main benefits include producing uniform, precision-finished samples that are corrosion-resistant and easy to handle. This enhances the accuracy and reliability of subsequent laboratory tests, while the sturdy steel construction ensures longevity and consistent performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cement Testing Equipment Category

Plunger Penetration Apparatus

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Dimension (L*W*H) : 20*15*20 Inch (in)

Cooling System : Other

Automatic Blaine Air Permeability Tester

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Dimension (L*W*H) : 30*20*30 Inch (in)

Cooling System : Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry